What Is Thermal Imaging?

People radiate heat, or thermal energy, which can be captured by specialized thermographic sensors. Due to the absence of the need for light, this technology has acquired broad acceptance in various spheres, such as military monitoring, firefighting, human identification in the smoke, fog, and haze, etc.

So, what is thermal imaging?

This article aims to answer this question in detail by revealing the scope of this technology’s implementation, specifics of thermographic hardware and software, and particular use cases for it. We also deal with the question, “what is the principle of thermal imaging” to let you understand the technology in simple terms and make a decision about its relevance for your needs.

Scope of Application

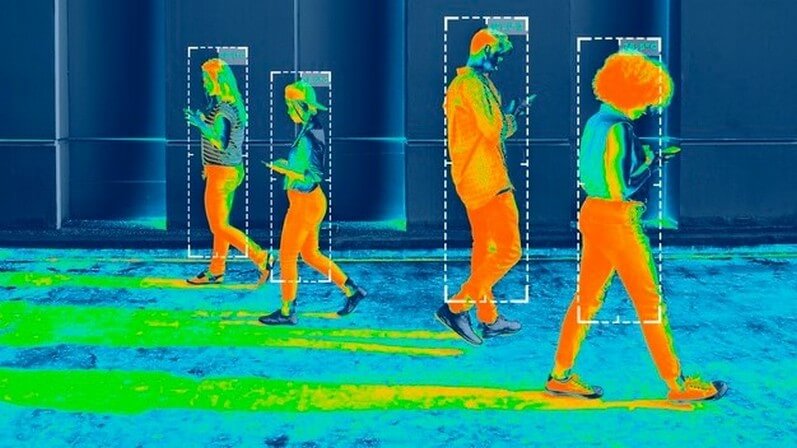

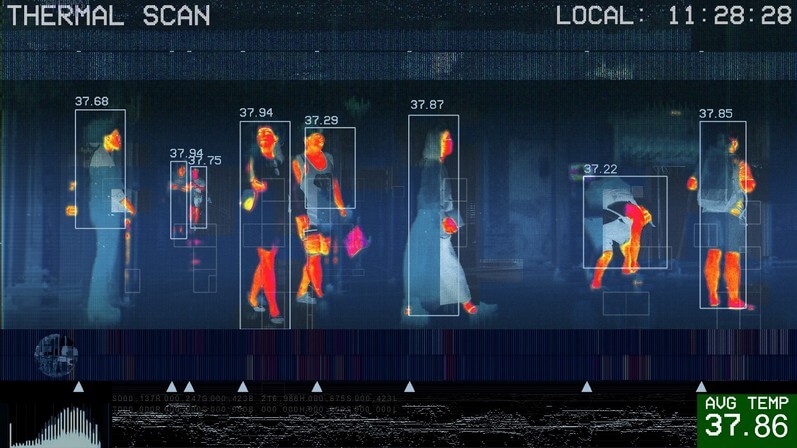

Before we proceed to discuss the sphere of this technology’s use in practice, let’s find out, “what does a thermal imaging device detect” As it was mentioned above, thermographic sensors typically capture the heat of human objects – the thermal energy radiated by every human body and allowing to compose a thermal image of a person, a dog, or another object. These sensors identify heat by using infrared energy capture, thus achieving a great degree of precision and creating multi-colored images of human beings in the grayscale (non-living) background.

Another question worrying many beginners is, “can thermal imaging see through glass” Unfortunately, thermal sensors cannot capture the heat behind a glass because they typically measure the heat profile of the building’s exterior, without an ability to access the internal objects.

Military Applications

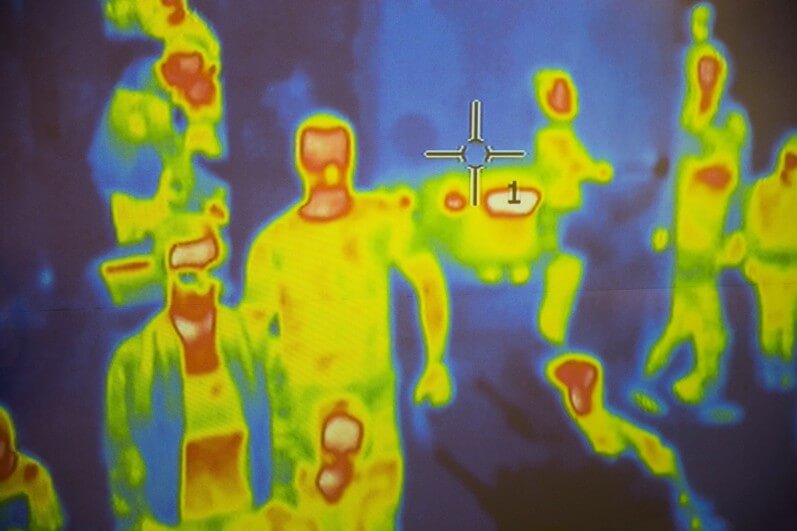

The military thermal imaging equipment is varied, applied in numerous spheres ranging from intelligence to field operations. Military personnel often have to act in the low visibility environments because of the smoke and fog resulting from weaponry use. Thus, by applying thermographic sensors, they can identify the enemies and allies even in the night, achieving high precision of military operations and minimal civilian damage.

Security and First Responders

Decision-making in low-vision environments is a challenge for security personnel and first responders. Thus, thermal imaging systems enable them to see in total darkness, able to assess the environment, detect threats and intruders in a timely manner, avoid collisions with other objects, conduct easier navigation, and perform search and rescue missions efficiently.

Monitoring and Detection

Long-range thermal cameras are invaluable instruments for the security personnel tasked with threat monitoring and detection. They enable officers to identify suspicious or aggressive behavior early to respond to the threat promptly and avoid damage. Besides, law enforcement and security officers can observe suspect activities from a safe distance for some time, deciding when to move in based on the obtained information.

Besides, thermal sensors are highly useful in industrial settings with hard access for human controllers. For instance, thermographic equipment can detect leakages in the industrial plants, monitor high- and low-voltage installation, turbines, compressors, and a broad range of electrical or mechanical equipment for robust anomaly detection and damage prevention.

Multispectral Imaging

As its name suggests, the multispectral imaging equipment can capture various characteristics, for instance, light and heat emission. In a nutshell, it’s a type of imaging capturing light from a narrow range of wavelengths across the electromagnetic spectrum. Such images can’t be created with usual cameras; you need a specialized lens separating wavelengths with the help of special filters. Besides, such images can be done with the help of UV or IR capturing cameras and sensors. Multispectral imaging is widely used in remote sensing, military target tracking, land mine detection, document and painting authenticity analysis, farming, forensics, and healthcare.

Detectors for Thermal Imaging

Now that we know, “What is thermal imaging used for” it’s time to proceed to more technical details. Here we uncover how thermographic equipment works, and what detectors it should include to function properly.

So, what devices use thermal imaging? In terms of detector type, all thermal detectors are divided into cooled and uncooled infrared sensors. The latter are smaller in size and have fewer moving parts, which contributes to their better usability. Besides, they cost less than cooled sensors. However, their spectrum is also quite limited, making them applicable only in specific settings.

Other thermographic detector classifications are also popular. For instance, you can distinguish InSb, InGaAs, and HgCdTe detectors when focusing on the technology they use. Besides, detectors are classified in terms of wavelength they can capture, divided into short, middle, and long wavelength equipment.

Let’s consider an example of the firefighter thermal imaging camera.

- it contains detectors for the identification of the fire source

- it can determine dangerous elements in specific settings

- it locates ventilation points

- it identifies residual hot spots

- it helps to find emergency fallback routes

Another aspect to learn when mastering the thermographic equipment is the color palette of thermal images and its interpretation. What do the colors mean in thermal imaging? Here, you need to keep in mind that the primary color of a thermal image is grayscale, meaning that the objects displayed on the monitor don’t have a heat profile specified in the device’s settings. Next come the following colors:

- brighter colors (like red, orange, and yellow) stand for warmer temperatures

- purple and dark blue colors stand for cooler temperatures

- black or gray color stands for the surrounding environment emitting no heat

Thermal devices differ in terms of their sensitivity, so the intensity of colors displayed by them may differ depending on this characteristic. Devices with 0.010C sensitivity can capture temperature variations within one-hundredth of a degree, thus giving the user a more nuanced understanding of the studied object’s thermal profile.

Optical Components for Thermal Imaging

The question “can thermal imaging see through glass” interests many users. It is also related to the question, “can thermal imaging see through walls”

The answers to both questions are “no” suggesting that movies lie. Thermal cameras can’t access the heat profiles of people inside a building if a glass separates the camera and the insiders; glass generally acts as a mirror for infrared radiation. In terms of walls, infrared radiation also cannot intercept through thick walls, so you cannot measure the heat profiles this way.

This simple truth is easily explained if one looks at the optical components of any thermal imaging camera. Its constituents are:

- An objective lens

- Thermal sensor (microbolometer)

- Electronic processing unit

- Microdisplay and eyepiece for viewing the produced images.

Lens Type and Design

The key part of any thermal imaging sensor is its lens, which influences its performance and the range of temperatures it can measures. Thus, you receive a specific thermal imaging picture depending on what lens you choose.

Your detection range will depend on the lens’s focal length, with greater length giving longer detection ranges. Still, you will need to sacrifice the field of view for the sake of magnification and range increase.

What are the different types of thermal imaging? Depending on the sphere of their application, you can distinguish four major types of such equipment:

- Thermocouples

- Thermistors

- Semiconductor-based integrated circuits (ICs)

- Resistance temperature detectors (RTDs).

Materials, Surfaces, and Coatings

Lenses for a thermographic camera are typically made of single-crystal germanium or chalcogenide glass. Such materials as sapphire, zinc selenide, silicon, and polyethylene possess the properties of MWIR and LWIR transmission, so their application in thermal imaging lens production is also common.

Germanium is a costly material, so many producers try to minimize its use when manufacturing a thermal imaging radar. Thus, you can come across the use of lenses with spherical or aspherical surfaces. Protective coating for these lenses is made of diamond-like carbon (DLC) or materials with similar durability and resilience parameters.

Assembly and Mechanical Design

If you’re interested in the manufacturing process of thermal imaging sensors, here is a simple breakdown of the mechanics and steps:

- You need to double-check all specifications of the assembly parts to ensure that your thermal imaging cameras will work as they should.

- Next comes the actual assembly of all physical components and the device’s calibration to fine-tune the system for its intended purpose.

- Cameras with moving components, e.g., with a zoom lens, require additional calibration efforts to achieve accuracy and smooth movement of parts during operation.

- Controllers should check the camera’s operation by changing the environmental conditions and checking how the sensor’s output changes with the environmental changes.

Thermal Imaging Applications

When you start looking for a thermal imaging app, you may be overwhelmed by a huge number of offers on the market. Thermographic software offerings are varied and diverse, depending on your specific use cases and environment of application. Complete thermographic suites enable end-to-end thermal data collection, analysis, and reporting. Advanced apps enable automated thermogram analysis and selection from large sequences, while specialized programs can be installed on your PC or laptop to derive thermographic stats directly from your infrared camera and other equipment.

Still, notwithstanding the abundance of offers in the market today, you may find it difficult to find an app fitting all your needs and including all the desired features. On the one hand, buying a comprehensive package may be too costly as you will be paying for numerous redundant features. On the other hand, opting for limited packages may restrict the use of software the way you want, while branded software rarely allows extensive user customization.

Thus, a good option is to design your own thermographic software with the help of ADUK experts. ADUK has been functioning on the market of thermal imaging software development for years, and it has built a positive track record by delivering affordable and customizable solutions. Try the service today to see how thermographic application evolves based on your needs and business objectives, receiving a strategic monitoring and analysis tool from pros.

Conclusion

Now that you know where thermal imaging is used and what makes thermal imaging cameras useful, it’s time to embrace this technology for your business benefits. Whether you need a sensitive security system or wish to advance your monitoring and fault detection in industrial settings, you’ll definitely enjoy the advantages of applying thermal detectors in use. To get custom-tailored software to operate your thermal imaging equipment, contact the experts of https://aduk.de. Its professionals are experienced in software development focused on individual business needs and environments, thus ensuring that you’ll get the most from your thermal imaging system.

Recent Posts

- What Is an Exoskeleton Suit?

- Where can you use an ultrasonic motor?

- Smart Camera: System That You Can Use for a Wide Variety of Purposes

- Why Is the Smart Toothbrush Better Than a Regular One?

- Microcontrollers: An Integral Part of Embedded Hardware

- Air Quality Monitoring System: Why It’s So Important in Modern Realities