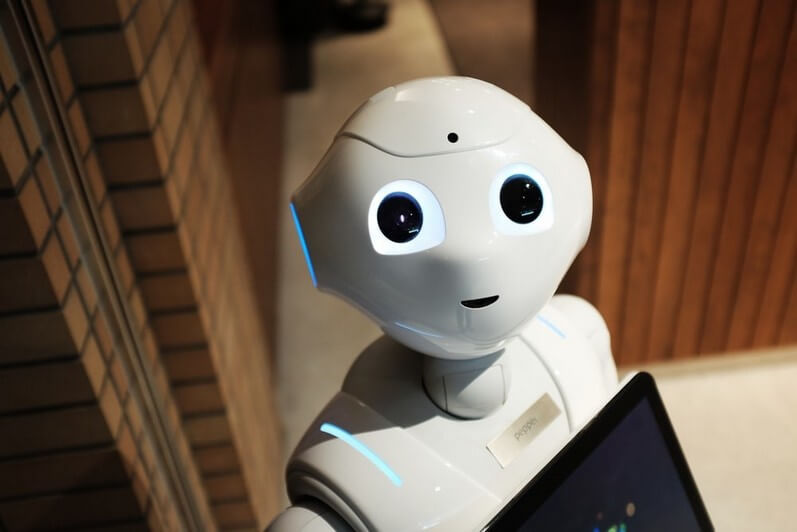

Robotic Automation Is the Future of Manufacturing

Automation is the buzzword today, with so many technological gains entering various business and industry domains. Robotics is a subtype of automation that stands for the use of automated, intelligent systems for the performance of industrial activities. So, with the world getting increasingly automated and efficient, all business owners specializing in product manufacturing need to delve deeper into the subject of manufacturing automation to introduce innovation, boost industrial performance, and attain greater efficiency and accuracy in production.

Automation Types

To understand the concept of robotics, you need to learn various types of automation first. At present, experts distinguish four types applied in industrial settings:

#1 Fixed automation

This is the simplest automation form presupposing the installation of automatic equipment programmed to perform a fixed set of tasks. These systems are most commonly used in mass production systems and assembly lines, requiring minor adjustments.

#2 Flexible automation

Flexible systems typically have a predefined set of various tasks they can perform and are operated by a human controller. The system’s operator inputs the code of the required operation and changes the set task once the requirements change.

#3 Programmable systems

While fixed systems perform a single, predetermined task, programmable varieties thereof should complete a sequence of activities. Thus, they are harder to create and are more sophisticated overall. Most of them contain complicated configurations and take much time for reprogramming.

#4 Totally integrated automation (TIA)

TIA is an evolution of all the systems mentioned above. It combines a set of independent production machines and orchestrates the sequence of their activities within a more complicated, compound production process. The sequence of such a system’s work is usually pre-scheduled and planned by experienced engineers.

Here are the existing production systems automation types, among which you may choose. They have emerged in response to the need to produce high-quality products and spare parts, meet significant production volume expectations, etc. Read on to find out about robotic machinery innovation and get workable solutions for your specific industrial settings.

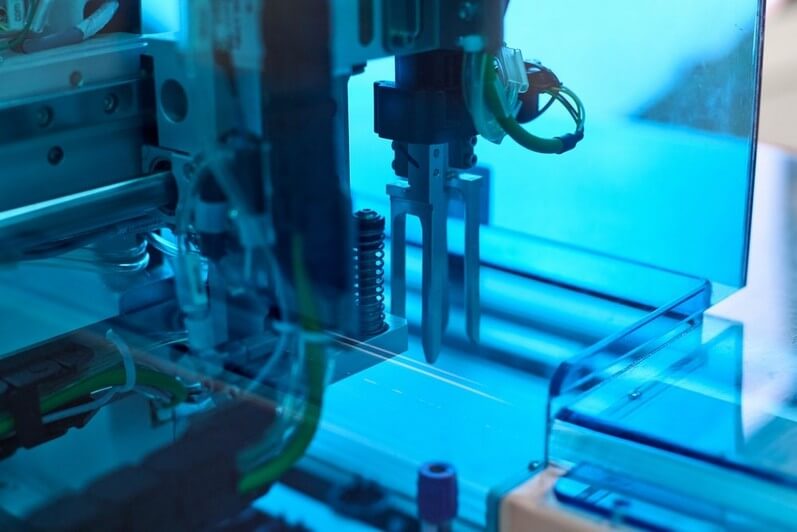

Industrial Automation: IoT Implementation

With TIA becoming more popular in modern factory settings, numerous IoT implementations have emerged to enable multi-machine collaboration and accurate sequencing of their actions. The development of industrial automation systems has taken the form of industry 4.0 – highly automated, interconnected industrial operations completed by factory robots and guided by smart algorithms.

This level of factory automation is frequently referred to as industrial IoT – a system of interconnected sensors, machines, and controllers networked in the industrial settings and programmed for the performance of specific production operations. Via the use of IoT in production, the business owners or production capacity operators can derive real-time data from the production line, making decisions and adjustments based on analytics. Besides, sophisticated IoT projects even enable dynamic system adjustments without human interference informed by data exchange and analysis among multiple devices of the IoT ecosystem.

The use of robotics in factories and the growing adoption of IoT technology in industrial settings helps achieve numerous strategic goals:

- Production systems become more effective

- Business owners achieve considerable cost savings by investing in durable and smart automated systems

- Automated systems are easily adjustable to changing production requirements if operated by skilled engineers

- As a result of automation, businesses become more flexible and responsive to the dynamically changing market situation

So, if you’re attracted to the idea of setting your own IoT system in industrial settings, consider the following components of such a solution.

#1 Hardware

Any IoT system connects hardware, like cameras, sensors, and robots, into an interconnected, well-tuned organism that completes the predetermined set of tasks. Thus, your system won’t have the operational force or data collection devices to function correctly without the needed hardware components.

#2 Software

Once all the hardware is collected in one place, you need to ensure that it communicates with one another to perform your IoT system’s broader goals and functions. This is typically done with specific software and connectivity technology, such as Wi-Fi, 4G, or cellular connection.

#3 Cloud Storage

Every IoT product functions based on the data it derives from sensors and cameras. This data accumulates and soon occupies too much space to handle it effectively on-site. Thus, it’s advisable to use cloud data storage services to ensure real-time access to production data and, at the same time, avoid costly investments in on-site data centers.

#4 Data

Next comes the data that will inform your IoT system’s activities. You need to decide what data will be collected via IoT sensors and the parameters of the norm and deviation from the norm. Feed those data parameters into the IoT system to let it analyze data in real-time to perform the set tasks efficiently.

#5 Dashboard

Though innovation is unstoppable today, even smart IoT systems require human control and interference from time to time. To check whether your system works as it should and performs all the programmed tasks properly, you will need a dashboard. The latter includes all data and device data to check, reports, and analytical visuals for quick status assessment.

Develop Your Own Automation System

As you can see, industry automation is gaining momentum in production settings today as business owners embrace the potential of such systems. Numerous developments in lasers and robotics have helped people attain greater degrees of productivity, measurement precision, real-time process and parameter tracking, and other production benefits. Thus, if you’re interested in high-precision, flawlessly operating, and fully customized factory automation systems, feel free to partner with ADUK experts.

ADUK.de has been operating in the hardware and firmware production niche for over a decade now, and its professionals and engineers can deliver the best automation solutions fitted explicitly to your industry specifics. We have numerous cases of production hardware customization and end-to-end development to showcase our talent and expertise in this innovative area. Contact us today to get a free quote and consulting on your project needs.

Recent Posts

- What Is an Exoskeleton Suit?

- Where can you use an ultrasonic motor?

- Smart Camera: System That You Can Use for a Wide Variety of Purposes

- Why Is the Smart Toothbrush Better Than a Regular One?

- Microcontrollers: An Integral Part of Embedded Hardware

- Air Quality Monitoring System: Why It’s So Important in Modern Realities